フローティング・フーム・フェンダー 高エネルギー吸収 優れた衝撃耐性 沈めない構造

記述

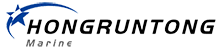

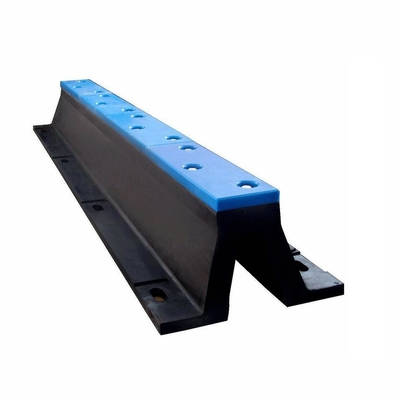

フローティング・フーム・フェンダーは,要求の高い港,造船場,オフショア環境のために設計された高性能の海洋保護ソリューションです.封閉細胞ポリエチレン泡のコアと強化されたエラストーマーまたはポリウレタン外皮を組み合わせた信頼性の高いエネルギー吸収,構造の回復力,そして空気漏れのリスクなしに長期耐久性を提供します.

このフェンダーは重複した高負荷下で 安定したパフォーマンスを提供するように設計されています外部保護層は磨きに優れた耐性を保証している海水,紫外線,厳しい気象条件. 浮遊泡のフェンダーは,気圧フェンダーとは異なり,膨張や圧力モニタリングを必要としません.運用リスクと保守コストを大幅に削減する.

広範囲の直径と長さで利用可能で,浮遊泡フェンダーは,特定の船舶のサイズ,停泊エネルギー,および設置条件に合わせてカスタマイズすることができます.チェーンなどのオプションのフィッティングフレンジやマウントブレーキットは,クイーの壁,イルカ,または浮遊構造に柔軟な統合を可能にします.

機能的な観点から,この製品は,停泊時の衝撃力を最小限に抑え,構造的なストレスを軽減し,船舶と港湾インフラストラクチャの両方を保護するように設計されています.整体的なドッキングの安全性を向上させる沈めない設計により,外側の皮膚が損傷した場合でも継続的な保護が保証され,重要な海上操作に信頼性の高いソリューションとなっています.

ケース・スタディ コンテナ・ターミナル停泊のアップグレード

東南アジアのコンテナターミナルで3万万5万 DWTのコンテナ船を運航している.古くなったゴムフェンダーにより,頻繁にケイダメージを受けた.5mが泊まりラインに沿って設置されました.

設置後,船の泊まりへの影響は40%以上減少し,保守停止時間は大幅に減少し,運用者は潮流変動においてもよりスムーズな泊まりを報告しました.このソリューションは,ターミナルオペレーターからの肯定的なフィードバックを受けて,さらに3つの泊場に再現されました.

仕様

| 製品名 |

フローティング・フーム・フェンダー |

| 製品タイプ |

閉ざされたセルで泡で満たされた浮遊用フェンダー |

| 基本材料 |

高密度閉細胞ポリエチレン泡 |

| 外皮 |

強化ポリウレタンまたはエラストメリックゴム |

| 浮気力 |

沈む こと が でき ない ポジティブな 浮気 力 |

| エネルギー吸収 |

低反応力を持つ高エネルギー吸収 |

| 耐候性 |

紫外線,海水,老化 に 耐える |

| 設置 |

チェーンまたはブレーケットの固定,カスタマイズ可能 |

| 奉仕 生活 |

15~20年 通常の運行条件下 |

|

直径 × 長さ

|

エネルギー吸収 60%

|

反応力 60% コンプ

|

体重 約

|

|

(mm)

|

(kNm)

|

(kN)

|

(kg)

|

|

300 × 1000

|

3.8

|

54

|

11

|

|

500 × 1000

|

10.6

|

91

|

41

|

|

600 × 1000

|

15.3

|

109

|

49

|

|

600 × 1000

|

18.3

|

131

|

55

|

|

700×1500

|

31

|

191

|

85

|

|

750×1500

|

36

|

204

|

89

|

|

900×1800

|

62

|

294

|

140

|

|

1000 × 1500

|

64

|

272

|

125

|

|

1000 × 2000

|

85

|

363

|

170

|

|

1200 × 2000

|

122

|

436

|

275

|

|

1200 × 2400

|

146

|

523

|

365

|

|

1250 x 2000

|

132

|

454

|

353

|

|

1250 × 2500

|

165

|

567

|

410

|

|

1500 × 3000

|

286

|

817

|

570

|

|

1500 × 4000

|

381

|

1089

|

720

|

|

1700 x 3000

|

367

|

926

|

700

|

|

1700 x 3500

|

428

|

1080

|

780

|

|

1800 x 3000

|

412

|

980

|

850

|

|

1800 x 3600

|

494

|

1176

|

965

|

|

2000 x 3000

|

508

|

1089

|

965

|

|

2000 x 3500

|

593

|

1271

|

1100

|

|

2000 x 4000

|

678

|

1452

|

1220

|

|

2400 × 4000

|

976

|

1743

|

1720

|

|

2400 x 4800

|

1171

|

2091

|

2140

|

|

2500 × 4000

|

1059

|

1815

|

1865

|

|

2500 × 5000

|

1324

|

2269

|

2500

|

|

2500 × 5500

|

1456

|

2496

|

2675

|

|

2700 x 5400

|

1668

|

2647

|

2865

|

|

3000 × 5000

|

1925

|

2750

|

3200

|

|

3000 × 6000

|

2287

|

3268

|

3740

|

|

3300 x 6500

|

2998

|

3894

|

4735

|

|

3600 x 7200

|

3953

|

4706

|

5800

|

|

4000 × 8000

|

4522

|

5809

|

8700

|

|

4200 × 8400

|

6277

|

6405

|

10000

|

|

4500 x 9000

|

7720

|

7353

|

10700

|

特徴

高エネルギー吸収能力

発泡コアは衝撃エネルギーを均等に分散し,船体とケイ壁のピークストレスを軽減します.この設計は,過剰な反応力なしで,大きな移動船のための安全な停泊を可能にします.

磨き 耐える 紫外線 耐える 外皮

強化されたエラストメリックコーティングは,重複した容器接触による磨損に抵抗し,長時間紫外線にさらされても構造の整合性を維持します.熱帯環境や海上環境での長寿を保証する.

沈めない メンテナンスの 必要 が ない 設計

外皮が損傷した場合でも,閉細胞泡は水の浸透を防ぎ,沈むリスクをなくし,充気型システムと比較して保守要件を最小限に抑えます.

潮流条件下での安定したパフォーマンス

浮遊設計により,フェンダーは水位変化に自動的に適応し,変動する潮流範囲で効果的な保護を維持できます.

申請

商業港とコンテナターミナル

コンテナ船,卸貨船,一般貨物船の頻繁な停泊のために設計された.

造船所 と 修理 港

船舶の整備,改装,ドライドックへの入港作業中に船体保護を提供します.

沖合の停泊と浮遊構造物

浮遊船,オフショアプラットフォーム,一時的な船舶施設に適しています.

香港海上船団を選んだ理由

証明されたエンジニアリングの専門知識

港航海は海上フェンダー設計に豊富な経験を持ち,現実の運用課題に合わせたソリューションを提供しています.

カスタムデザイン能力

船舶の種類 泊まり場構造 エネルギー要件に基づいて パーソナライズされたフェンダーサイズ 皮膚材料 固定システムを提供します

高品質 の 材料 の 選択

耐久性,安全性,国際基準の遵守を保証するために,船舶級の泡と認証されたエラストメリックコーティングのみが使用されます.

販売後の包括的なサポート

設置ガイドから 長期的性能評価まで 私たちの技術チームは 製品ライフサイクルを通して 顧客を支援します

よくある質問

1フローティング・フーム・フェンダーにはどのサイズが利用可能ですか?

標準直径は500mmから4,500mm以上で,要求に応じてカスタム長が利用可能である.

2極度の温度で使えますか?

そうです 材料は -40°Cから +80°Cの温度で 信頼性の高い性能を 備えるように設計されています

3証明書はあるか?

製品には,CCS,BV,DNVなどの第三者の検査証明書が要求される.

4防護具はどうやって設置してるの?

施設の条件に応じて鎖,ブレーキ,または浮遊システムによって設置することができます.

5期待される使用寿命は?

適正に選べば使用寿命は15~20年を超えます

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!