ドックフェンダー 耐候性 腐食性 低保守性

記述

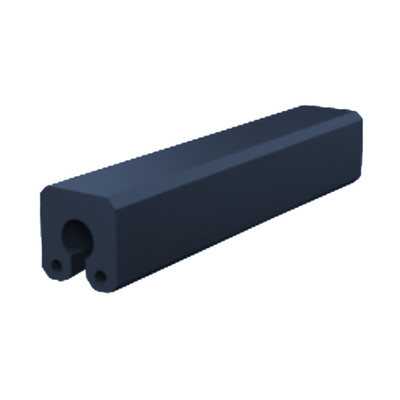

浮遊泡フェンダーは,港,造船場,ドライドック業務のために設計された汎用的で高性能なフェンダーシステムです.強化されたポリウレタンまたは合成ゴム皮に包まれた閉細胞ポリエチレン泡のコアから作る沈めない水面設計により,停泊,ドッキング,船の安全を保証します.膨張や圧縮を必要としない維持作業.

800mmから3,500mmまでの直径と1mから5mの長さで利用可能で,これらのフェンダーは,小型リグボートから5万WTの卸貨船まで,船を収容することができます.外皮の磨き耐性熱帯の港,工業造船場,そして交通量が多い泊場での長期使用に適しています.

フレンダーの設計により,潮流変動に適応し,一貫した船体保護を提供し,堤防,ドライドック,浮遊ポントンにおける構造的ストレスを最小限に抑える.船体損傷やインフラストラクチャの破損のリスクを軽減する運行安全を高め 維持費を削減し 港の全体的な効率を向上させる

ケーススタディ ヨーロッパのドライドック施設

ヨーロッパで卸貨船と化学タンカーを運航するドライドックでは,船が頻繁にドッキングする事で,伝統的なゴムフェンダーの構造が破損し,船体が軽く損傷しました.1 の直径の浮遊泡フェンダーがインストールされましたドライドックの壁に沿って200mmと3mの長さ

結果: 防護具は,繰り返し停泊するドライドックでの回転時間を20%短縮し,操作者は,長時間耐久性,保守不要な設計,そしてエネルギー吸収がスムーズです複数のドックや泊場で採用されるようになった.

仕様

| 製品名 |

フローティング・フーム・フェンダー |

| 製品タイプ |

閉ざされたセルで泡で満たされた浮遊用フェンダー |

| 基本材料 |

高密度閉細胞ポリエチレン泡 |

| 外皮 |

強化ポリウレタンまたはエラストメリックゴム |

| 浮気力 |

沈む こと が でき ない ポジティブな 浮気 力 |

| エネルギー吸収 |

低反応力を持つ高エネルギー吸収 |

| 耐候性 |

紫外線,海水,老化 に 耐える |

| 設置 |

チェーンまたはブレーケットの固定,カスタマイズ可能 |

| 奉仕 生活 |

15~20年 通常の運行条件下 |

|

直径 × 長さ

|

エネルギー吸収 60%

|

反応力 60% コンプ

|

体重 約

|

|

(mm)

|

(kNm)

|

(kN)

|

(kg)

|

|

300 × 1000

|

3.8

|

54

|

11

|

|

500 × 1000

|

10.6

|

91

|

41

|

|

600 × 1000

|

15.3

|

109

|

49

|

|

600 × 1000

|

18.3

|

131

|

55

|

|

700×1500

|

31

|

191

|

85

|

|

750×1500

|

36

|

204

|

89

|

|

900×1800

|

62

|

294

|

140

|

|

1000 × 1500

|

64

|

272

|

125

|

|

1000 × 2000

|

85

|

363

|

170

|

|

1200 × 2000

|

122

|

436

|

275

|

|

1200 × 2400

|

146

|

523

|

365

|

|

1250 x 2000

|

132

|

454

|

353

|

|

1250 × 2500

|

165

|

567

|

410

|

|

1500 × 3000

|

286

|

817

|

570

|

|

1500 × 4000

|

381

|

1089

|

720

|

|

1700 x 3000

|

367

|

926

|

700

|

|

1700 x 3500

|

428

|

1080

|

780

|

|

1800 x 3000

|

412

|

980

|

850

|

|

1800 x 3600

|

494

|

1176

|

965

|

|

2000 x 3000

|

508

|

1089

|

965

|

|

2000 x 3500

|

593

|

1271

|

1100

|

|

2000 x 4000

|

678

|

1452

|

1220

|

|

2400 × 4000

|

976

|

1743

|

1720

|

|

2400 x 4800

|

1171

|

2091

|

2140

|

|

2500 × 4000

|

1059

|

1815

|

1865

|

|

2500 × 5000

|

1324

|

2269

|

2500

|

|

2500 × 5500

|

1456

|

2496

|

2675

|

|

2700 x 5400

|

1668

|

2647

|

2865

|

|

3000 × 5000

|

1925

|

2750

|

3200

|

|

3000 × 6000

|

2287

|

3268

|

3740

|

|

3300 x 6500

|

2998

|

3894

|

4735

|

|

3600 x 7200

|

3953

|

4706

|

5800

|

|

4000 × 8000

|

4522

|

5809

|

8700

|

|

4200 × 8400

|

6277

|

6405

|

10000

|

|

4500 x 9000

|

7720

|

7353

|

10700

|

特徴

複数の容器によるエネルギー吸収

閉ざされた細胞の泡コアは,船舶の船体やドック構造に過度の負荷を転送することなく,さまざまな船のサイズやタイプに対応し,衝撃力を効果的に分配します.これは,フェンダーを1泊場で複数の船舶の種類を扱う港に理想的になります.

高度 の 磨き 耐性 と 紫外線 耐性

強化された外皮は,機械的磨損,紫外線曝露,海洋腐食から泡コアを保護し,交通量が多い港やドライドック環境でも長続きする性能を保証します.

潮流 に 適応 し て 漂う 性能

フローティングデザインにより,フェンダーは水位の変化に自動的に適応し,潮流変動,波動,および波動するドック水深の間で継続的な保護を維持することができます.

簡単 に 設置 し,位置 を 変更 する

頑丈な性能にもかかわらず 防護具は効率的な設置と位置変更のために設計されていますドライドック運用や重荷搬送設備や専門スタッフなしで一時的な港の配置を支援する.

申請

港湾の停泊事業

コンテナ船,卸貨船,一般貨物船,リグ船を停泊中に保護し,船体ストレスとクイア磨きを軽減します.

ドライドックと整備施設

検査,修理,リフィット作業中に船舶の船体を保護し,船舶とドックの壁の両方に損傷を防ぐ.

浮遊船 と 臨時 的 な 泊場

臨時的なドッキング・アレンジメント,浮遊プラットフォーム,建設・保守現場の影響緩和を図る.

香港海上船団を選んだ理由

多目的海洋施設での経験

港湾,造船所,ドライドック施設の汎用フェンダーソリューションを提供して,さまざまなアプリケーションで一貫したパフォーマンスを確保する豊富な経験を有する.

設計オプションをカスタマイズする

適正な直径,長さ,固定メカニズム,外皮材料を 特定の泊まり条件と船種に合わせて提供し,最適な保護と長寿を保証します

高級 素材 の 選択

防護具は海上用ポリエチレン泡と 高性能ポリウレタンコーティングを使用します 優れた耐磨性,UV安定性,内陸およびオフショアの両方の用途に適した防腐性.

専門技術支援

Hongruntong Marineは,インストールガイドライン,性能評価,検査勧告を含む,ライフサイクル全体のサポートを提供します.信頼性の高い運用と最小限の保守コストを確保する.

よくある質問

1フローティング・フーム・フェンダーは 複数のタイプの船を 1 つの泊位で保護できますか?

そうです 泡の中核は 変化するエネルギーの衝撃を吸収するように設計されており 過剰な反応力なしで トラック船や貨物船や卸荷船に適しています

2このフェンダーは ドライドック操作に適していますか?

間違いなく 浮遊物で 衝撃に耐える設計で

3防護具には 特殊な装置が必要ですか?

いや,鎖,ブレーキ,あるいは一時的な浮遊システムを使って 固定できるし,効率的な操作と位置転換のために設計されています.

4港やドライドックでは 防護具がどれくらい耐えるの?

適切な選択と設置により,使用寿命は通常15年以上であり,頻繁にドッキングサイクルやUV露出でも使用できます.

5外皮が損傷した場合は,フェンダーを修理できますか?

小さい表面損傷はポリウレタンパッチで修復できますが 沈めない泡のコアは 継続的な動作を保証します

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!