海上フェンダー 船舶を効果的に保護する 停泊損傷を軽減する 高圧縮回復

記述

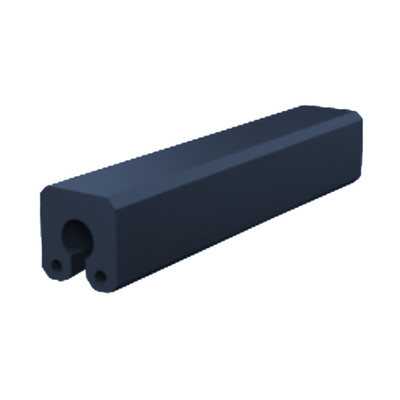

フローティングスポンフェンダーは,高速フェリー,旅客船,高速貨物船を含む高周波停泊作業のために特別に設計された高性能の船舶フェンダーです.閉ざされた細胞のポリエチレン泡のコアは沈めない性能を保証します強化されたポリウレタンまたは合成ゴムの外層は,優れた磨き耐性,UV安定性,腐食防止を提供します.継続的なドッキングサイクルで耐久性を維持する.

フレンダの浮遊性と適応性設計により,潮流変動と波動に自動的に調整し,ダイナミックな港環境で船体と泊場構造を保護することができます.軽量 で も 堅い600 mm から 2 mm までの直径で提供されます.500 mm,長さ1mから4m中型および大型旅客フェリー,高速キャタマラン,小型貨物船に適しています. メンテナンスの不要な設計により,稼働停止時間が短縮されます.信頼性と安全性が重要な高頻度泊場や 忙しい旅客ターミナルに最適化.

ケース・スタディ 高周波フェリーターミナル

地中海のフェリーターミナルで高速フェリーや小型旅客船を運航する 伝統的なゴムフェンダーは 連続したドッキングサイクルに耐えられませんでした船体に傷つき 整備の停滞時間が増加する敷地に沿って,直径900mm,長さ2.5mの浮遊泡のフェンダーが設置されました. 設置後,船が堤防への衝撃を最小限に抑え,回転時間が25%改善されました.維持が必要性が著しく減少しました運用者は,すべての船舶でよりスムーズなドッキング操作と一貫した保護を報告し,高周波の旅客ターミナル操作におけるフェンダーの信頼性を証明しました.

仕様

| 製品名 |

フローティング・フーム・フェンダー |

| 製品タイプ |

閉ざされたセルで泡で満たされた浮遊用フェンダー |

| 基本材料 |

高密度閉細胞ポリエチレン泡 |

| 外皮 |

強化ポリウレタンまたはエラストメリックゴム |

| 浮気力 |

沈む こと が でき ない ポジティブな 浮気 力 |

| エネルギー吸収 |

低反応力を持つ高エネルギー吸収 |

| 耐候性 |

紫外線,海水,老化 に 耐える |

| 設置 |

チェーンまたはブレーケットの固定,カスタマイズ可能 |

| 奉仕 生活 |

15~20年 通常の運行条件下 |

|

直径 × 長さ

|

エネルギー吸収 60%

|

反応力 60% コンプ

|

体重 約

|

|

(mm)

|

(kNm)

|

(kN)

|

(kg)

|

|

300 × 1000

|

3.8

|

54

|

11

|

|

500 × 1000

|

10.6

|

91

|

41

|

|

600 × 1000

|

15.3

|

109

|

49

|

|

600 × 1000

|

18.3

|

131

|

55

|

|

700×1500

|

31

|

191

|

85

|

|

750×1500

|

36

|

204

|

89

|

|

900×1800

|

62

|

294

|

140

|

|

1000 × 1500

|

64

|

272

|

125

|

|

1000 × 2000

|

85

|

363

|

170

|

|

1200 × 2000

|

122

|

436

|

275

|

|

1200 × 2400

|

146

|

523

|

365

|

|

1250 x 2000

|

132

|

454

|

353

|

|

1250 × 2500

|

165

|

567

|

410

|

|

1500 × 3000

|

286

|

817

|

570

|

|

1500 × 4000

|

381

|

1089

|

720

|

|

1700 x 3000

|

367

|

926

|

700

|

|

1700 x 3500

|

428

|

1080

|

780

|

|

1800 x 3000

|

412

|

980

|

850

|

|

1800 x 3600

|

494

|

1176

|

965

|

|

2000 x 3000

|

508

|

1089

|

965

|

|

2000 x 3500

|

593

|

1271

|

1100

|

|

2000 x 4000

|

678

|

1452

|

1220

|

|

2400 × 4000

|

976

|

1743

|

1720

|

|

2400 x 4800

|

1171

|

2091

|

2140

|

|

2500 × 4000

|

1059

|

1815

|

1865

|

|

2500 × 5000

|

1324

|

2269

|

2500

|

|

2500 × 5500

|

1456

|

2496

|

2675

|

|

2700 x 5400

|

1668

|

2647

|

2865

|

|

3000 × 5000

|

1925

|

2750

|

3200

|

|

3000 × 6000

|

2287

|

3268

|

3740

|

|

3300 x 6500

|

2998

|

3894

|

4735

|

|

3600 x 7200

|

3953

|

4706

|

5800

|

|

4000 × 8000

|

4522

|

5809

|

8700

|

|

4200 × 8400

|

6277

|

6405

|

10000

|

|

4500 x 9000

|

7720

|

7353

|

10700

|

特徴

高周波衝撃吸収

閉ざされたセルフームコアは,恒久的な変形なしに高速フェリーや小型貨物船からの繰り返しドッキング衝撃を吸収し,一貫した保護と船体ストレスを軽減します.

耐磨性や紫外線抵抗性のあるコーティング

強化された外層は,継続的な機械的磨き,UV露出,海水腐食下で構造的整合性を維持し,忙しいターミナルでフェンダーの使用寿命を延長します.

軽量 で 扱いに 容易 な

重荷性能にもかかわらず,フェンダーは軽量で,迅速なインストール,再配置,取り除くことが可能で,緊密な運用スケジュールを持つターミナルにとって重要です.

浮く 適応 的 な 設計

動的停泊作業中に船舶の最適なカバーを維持し,ドッキング効率と船舶の安全性を向上させ,潮と波の条件に自動的に調整します.

申請

高周波旅客ターミナル

高速フェリーや旅客船を保護し,ピーク期間中に安全性と効率的な回転を保証します.

中型貨物泊場

繁忙な港で小型貨物船と高速輸送船に信頼性の高い衝撃吸収を提供します.

浮遊 または 臨時 ピア

臨時的なドッキング施設,浮遊船,または季節的な泊まり場のために理想的です.迅速な展開と効果的な保護を提供します.

香港海上船団を選んだ理由

高周波操作の専門知識

港湾は船舶の移動が頻繁な港湾のために設計されたソリューションを提供し,一貫した安全性とパフォーマンスを保証します.

調整可能で柔軟なソリューション

ターミナルの要求,船舶の種類,泊まり頻度に合わせて 直径,長さ,設置オプションを提供しています

耐久 し た 耐久 性 の 材料

高品質 の 泡 と 強化 さ れ た 外部 コーティング は 磨損 に 耐久 し,UV 安定 し,腐食 に 防ぎ,停滞 時間 と 交換 費用 を 最小限に 抑え ます.

総合的な技術支援

ホンルーントング・マリンは,顧客に設置指導,検査,継続的なパフォーマンス評価をサポートし,高周波泊場での信頼性の高い運用を保証します.

よくある質問

1このフェンダーは 連続したドッキングサイクルに対応できるのか?

泡のコアは 永久的な変形なしに 高速で繰り返し 停泊する衝撃を吸収するように設計されています

2高速フェリーには適していますか?

乗客フェリー カタマラン 小型貨物船用で 高速で安定した保護を

3特別なメンテナンスが必要ですか?

最低限 肺動的で沈めない設計は 定期的な視察のみが必要です

4運用に柔軟性があるため 迅速に移動できますか?

軽量 な 設計 に よっ て,迅速 に 設置 し,位置 を 変更 し,保管 する こと が でき,季節 的 や 一時 的 に 泊まる 場所 に 最適 です.

5. 高周波操作における使用寿命は?

適正に選べば,継続的な日々のドッキングサイクルや日光,塩水,機械的磨損にさらされても使用寿命は15~20年です.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!